Create Production Lines in Allmoxy

Use production lines to organize your manufacturing workflows

Production Lines allow you to set up certain workflows inside Allmoxy that mimic what's actually happening on the floor. After setting up production line, you can track metrics between lines, use barcode scanning to track labor to each stage of the production line, and even dictate the appropriate start time so that every product in an order is completed at the same time.

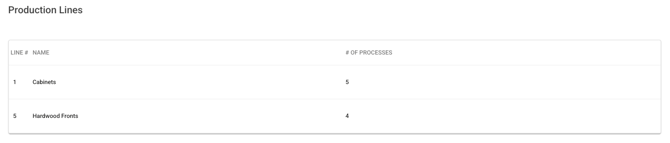

Create production lines in Allmoxy go to ⚙️ ➡️ Operations ➡️ Labor Processes. From here you can add a new production line:

Example: A door production line might include processes named cut, sand, assemble, finish, and wrap.Then, shop employees can clock into or track time to a process, like sanding, and scan each order as they sand OR they can just mark that they completed sanding for that job.

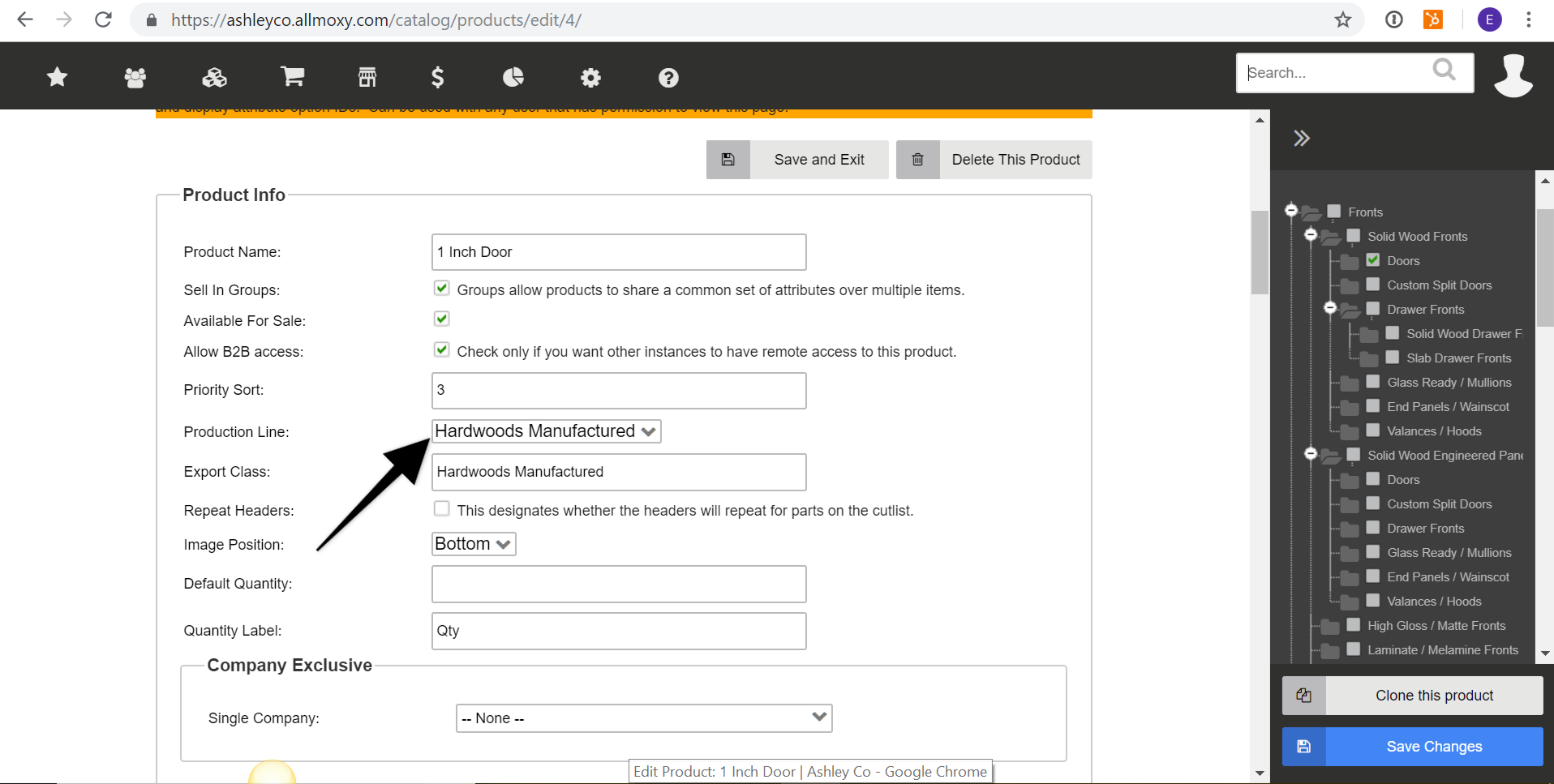

Once you've created the production line, you will need to assign the product(s) in your catalog that you want to run on that production line.

To do this: Go to ⚙️ ➡️ E-Commerce ➡️ Products.

Select which product you want to edit.

Click on the production line dropdown to designate which production line this product should run on.

Once set up, you can use the Work Schedule Report to start individual production lines within each order. You can also use the scanning station to track time to each step of the process, or just mark each stage as completed.