Job Tracking

Here's a quick tutorial on how you can track jobs through Allmoxy

You have two options when tracking jobs through the production process: manual entry or barcode entry. We'll quickly run through the manual entry and then explain how to set up barcode tracking.

The first thing to note is that you can not add order statuses. The existing statuses (ordered, verified, in progress, completed, etc) are fixed and can not be changed for individual customers.

However, you can set up Production Lines and Labor Processes to track what happens to an order during the In Progress stage. To learn about setting up your production lines, view this article here

In your production line, you want to create each step of the process. If you want to know how long it takes an order to get through machining, then create a Machining step in your production line and so on until you have your entire process included in your production line.

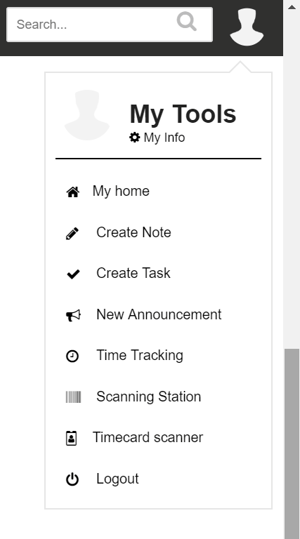

For manual job tracking, have your employee log in and then select Time Tracking from the drop down menu under their profile. Here, they can enter the date, order #, and select what they were doing. If you want employees to clock in and out, then they just need to click the Clock In/Out box. If you just want employees to enter what they did after completion, they can enter how long it took them (or not! this is optional) and then select Done.

You can also use scanners to enter this information:

We recommend setting up a scanning station (a tablet or small laptop with a scanner) at every step in your process for easier, quicker scanning. However, feel free to start small with one scanning station.

To start scanning, go to the same dropdown menu and select Scanning Station.

Here, simply scan your parts list or shipping ticket to update the status.

You will have to configure your scanner to enter the information from the barcode generated on your output pages. All scanners come with a set up manual that should walk you through this process.

We get several questions about which scanners are best. The best ones are whichever ones your team prefers! All seem to work well with Allmoxy.